NEWS STORY

ARTEC HANDHELD 3D SCANNER REVERSE ENGINEERING LEGACY TRACTOR EQUIPMENT

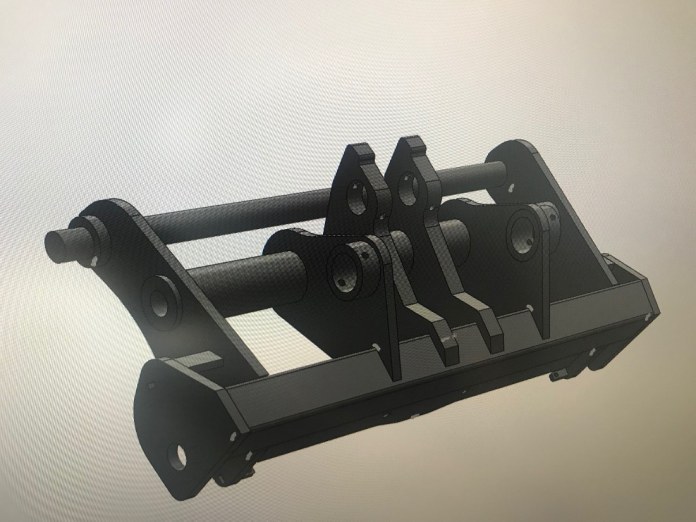

Taylor Attachments, a UK-based manufacturer of tractor headstock conversion brackets, frequently receives damaged equipment from its customers in need of restoration.

Normally, the company would sit down and spend hours manually drawing the parts needed to restore the piece of tractor equipment before making prototypes and revisions. The process altogether could take Taylor Attachments up to three weeks to complete: a lengthy and costly process.

The company came to Europac3D to look for a solution that would save it time and money in re-engineering legacy equipment.

As a gold-certified reseller of Artec 3D scanners, Europac 3D recommended the Artec Eva 3D scanner: a fast, affordable and easy-to-use 3D scanner, perfect for capturing medium-sized objects.

Quick to set up and easy-to-use, with extremely fast scanning, a 536 x 371mm capture window and the ability to grab 16 frames per second, large objects can be digitised with speed and efficiency – the Artec Eva 3D scanner is the market-leader in hand-held 3D scanning.

The object is stitched together frame-by-frame on the screen in real-time, allowing the user to see exactly what they have captured as the user moves around the object being captured.

Using the Artec Eva scanner, Taylor Attachments has reduced the time it takes to produce a digital model of the required equipment from weeks to just a single day.

“With Eva, it takes only about 20 minutes to scan an entire headstock, then another 20 minutes to post-process everything in Artec Studio – and after that, the 3D model from Studio is sent over to our in-house design team,” commented Mark Taylor of Taylor Attachments.

“What they do is use the Xtract3D add-in for SOLIDWORKS to create a beautiful, highly-precise 3D model that’s 100% ready for protection. After that, it’s immediately sent over to one of our laser cutting partners.

“What we are looking at in terms of individual project time with Eva? Everything from start-to-finish in less than 24 hours. That’s it. Compare that with the seven days to two-to-three weeks it took us when we were doing it the old way. There’s simply no going back for us.” finished Mark Taylor.

For more information on how businesses can use 3D scanners and get ahead of the competition, contact us today on (0)1270 216000 or via email at sales@europac3d.com

Artec Eva 3d scanning tractor headstock

Artec Eva handheld 3D scanner