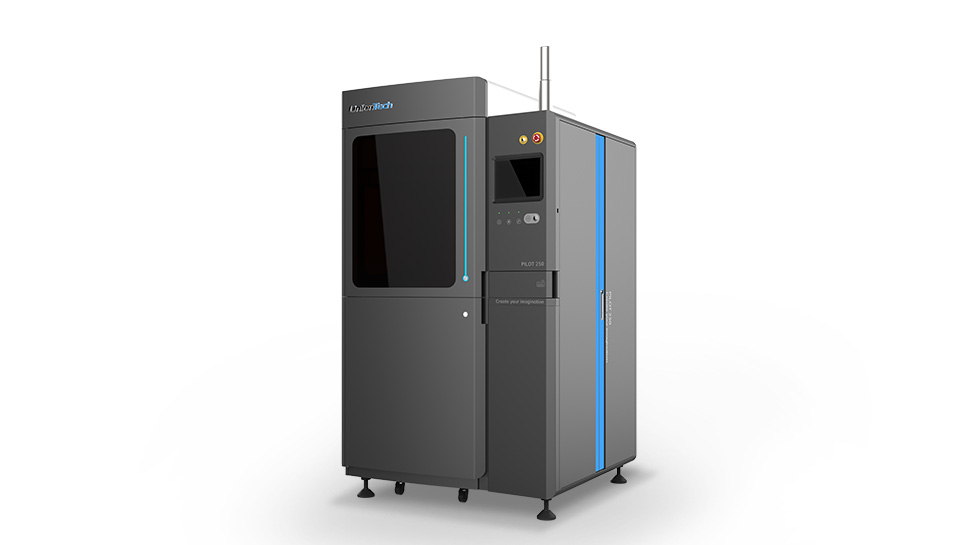

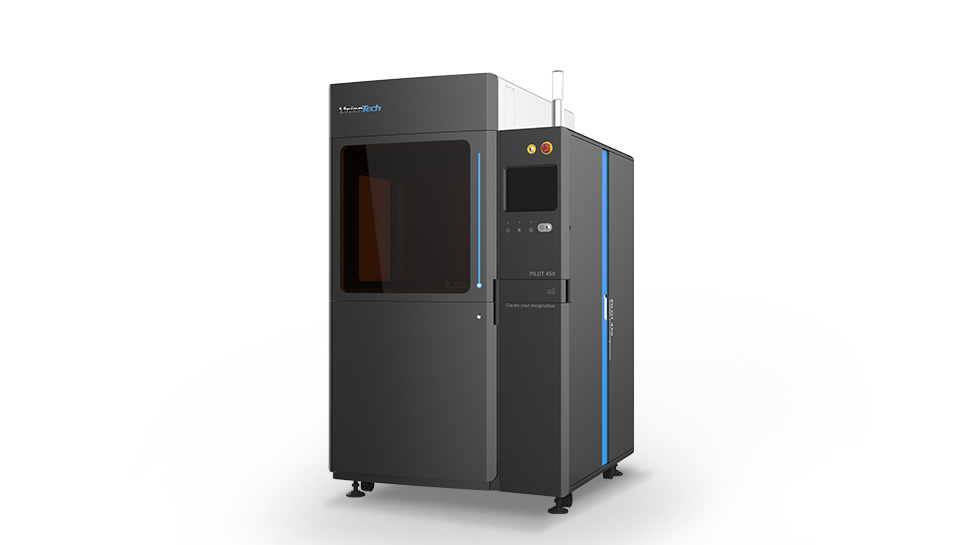

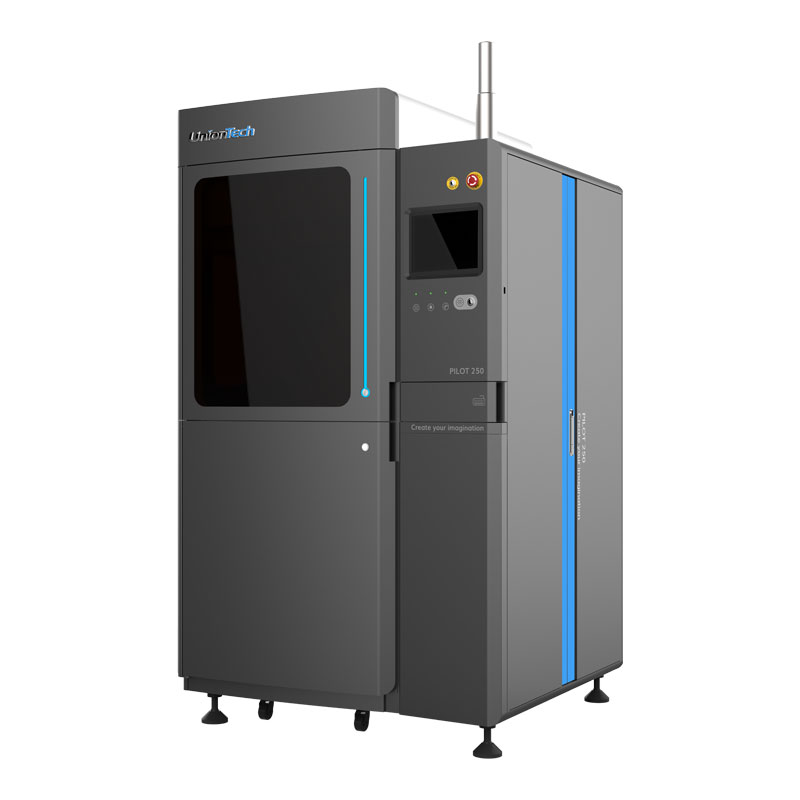

UNIONTECH PILOT SERIES SLA 3D PRINTERS

A NEW DIMENSION IN STEREOLITHOGRAPHY 3D PRINTING

The Pilot 250 and 450 SLA 3D printers from Uniontech are a fantastic choice for high quality small/medium sized components in the prototyping sector. A beam size of 0.08-0.12mm and layer thickness as low as 0.05mm create highly detailed parts with excellent surface finish.

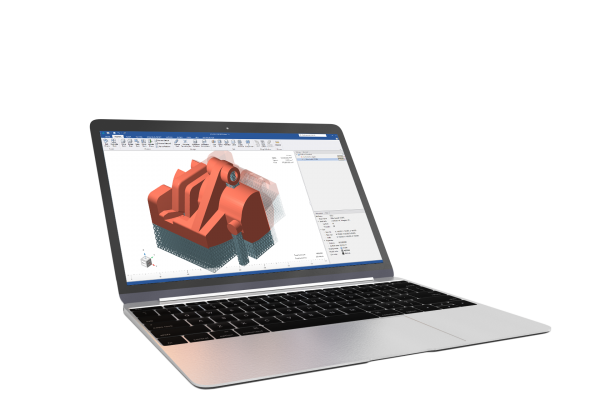

Open Source Application Driven 3D Printing

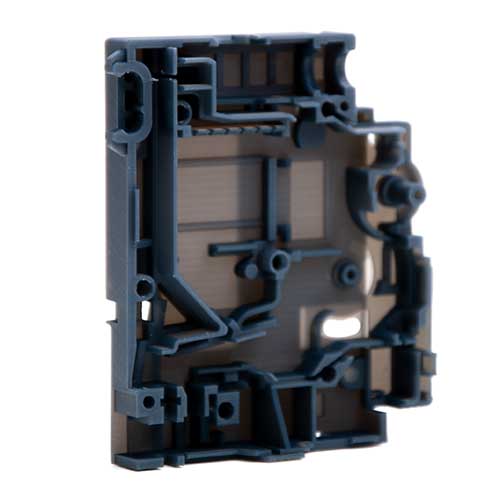

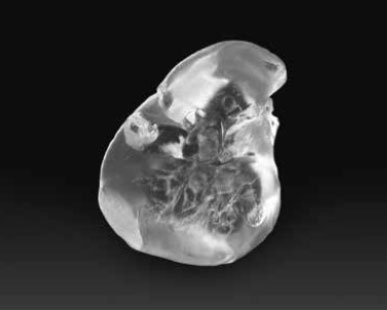

Uniontech have taken a unique approach to the market with a completely open source system with regards to software and more importantly additive manufacturing materials. This approach allows Europac3D to focus purely on the customer requirements and offer material solutions that meet the precise demands of the application, such as medical grade components, high temperature resistance and high impact strength.

High quality components sourced from around the world such as Panasonic, Spectra Physics, DSM and Advanced Optowave

Granite Recoater Frame helps create high quality parts with excellent sidewall properties and small details

Open Source platform with regards to materials allows for application driven sales

Isotropic strength in XYZ

Scanning Speed of 12-15 m/s

High quality mechanical build