Your future in 3D is HP Jet Fusion

A new era of additive manufacturing

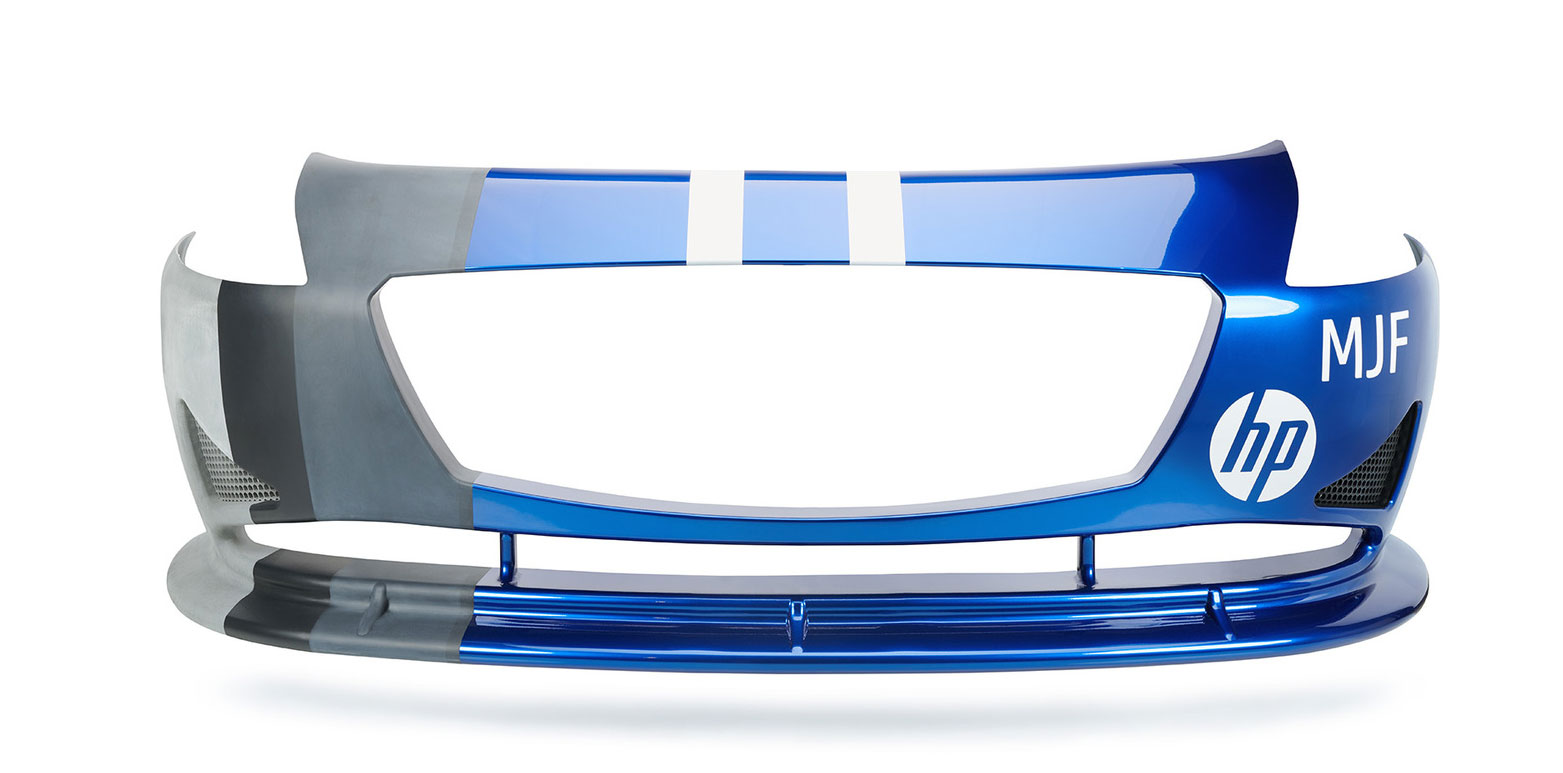

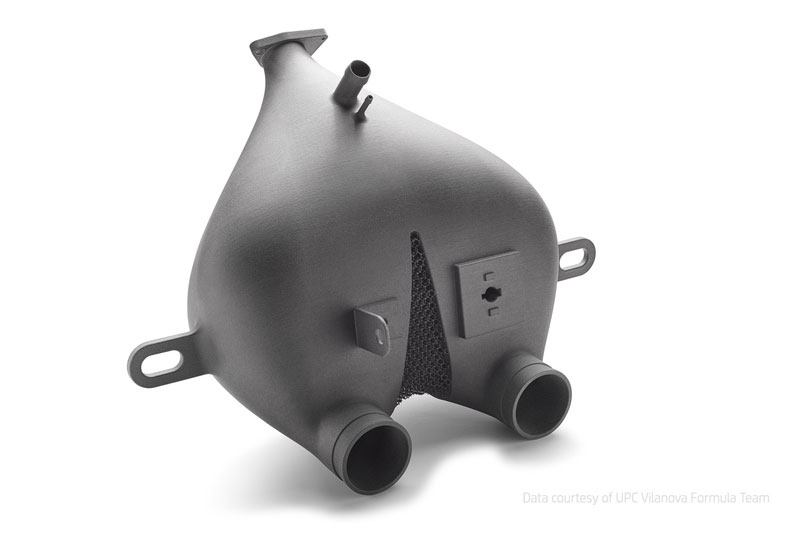

The next generation of 3D printing technology moves beyond Selective Laser Sintering (SLS) and is brought to you by HP Multi Jet Fusion. For those familiar with SLS you will be close to understanding this newer technology in additive manufacturing. From prototyping to production, HP Jet Fusion 3D printing technology is enabling industry from automotive to aerospace to bring their products to market faster than ever before. These 3D printing solutions provide speed, strength of part, accuracy and ground breaking economics – fundamental to an efficient manufacturing process.

What is SLS 3D printing?

Using the Selective Laser Sintering (SLS) 3D printing process, parts can be produced by building up sintered powdered material one layer at a time.

At the start of the process an initial layer of polymer powder is spread across the build platform. A cross section of the part is then selectively sintered by a laser, fusing the particles of powder together . A new layer of thickness is then laid down by the build platform and the process repeats until the part build is complete.

The resulting part is a component encased in unsintered powder. Once removed from the powder and cleaned the part is ready for use or post processing.

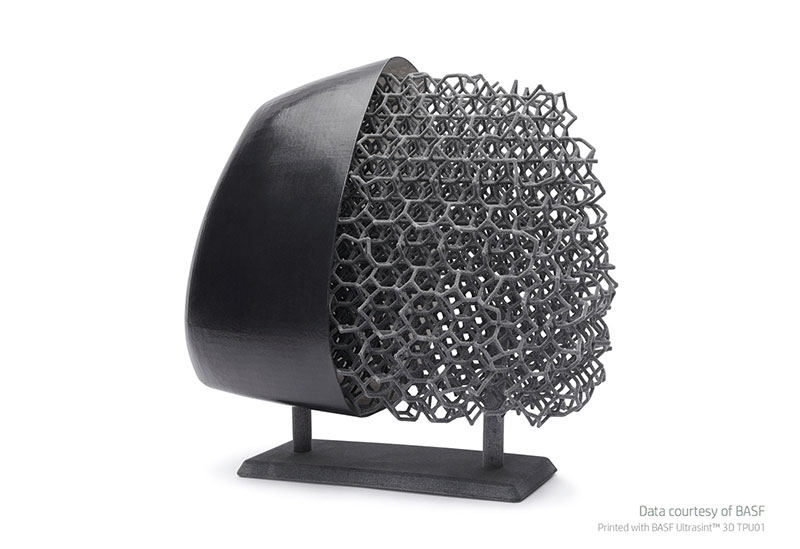

SLS additive manufacturing is characterised by its use of material. Selected for functional application, thermoplastics are best suited for manufacturing end use parts and functional prototypes. These materials possess good mechanical properties as well as high impact, abrasion and chemical resistance.