CASE STUDY

3D Scanning Solution for AER Stafford

UK-based plastic products supplier AER Stafford, which supplies plastic and foam parts to the likes of Jaguar, Aston Martin and Toyota, needed an accurate measuring solution to inspect key plastic automotive parts for an ongoing project the company was doing for the new Land Rover model.

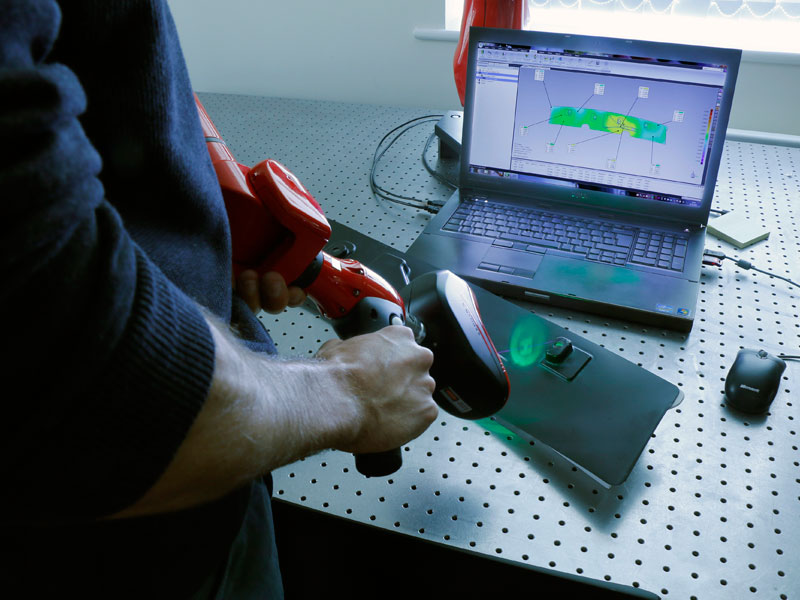

The company was looking to accurately scan and measure the details of a flexible, thin walled part to ensure that it had been manufactured correctly. AER turned to Europac 3D for advice and support as they were able to use a combination of the very latest laser scanning technologies available, including a traditional measuring arm and software to accurately measure and record the parts.

To accurately measure the part, Europac 3D designed and 3D printed a fixture that would hold the part in place without it being distorted by gravity or various pressure points. The part was placed on top of the fixture and vacuumed into place to allow for accurate laser scanning.

Using this approach, Europac was able to accurately capture the 3D data for a selection of challenging parts. This 3D scan data could then be accurately compared to the part’s 3D CAD model and any discrepancies in the dimensions identified by a simple colour coded over-mapping exercise.

AER Stafford was so impressed with the accuracy that they subsequently installed both a Kreon Ace 7-axis measuring arm and Zephyr II Blue laser scanner along with Geomagic Control metrology software.

The former, they found, allowed for increased flexibility and precision for capturing complex geometrical details. The ergonomic design also enabled users to scan easily for longer periods. The supporting software offered a completely streamlined process with minimal human interaction.

By using the latest 3D scanning technologies, AER Stafford has been able to accurately check the designs and dimensions of critical parts needed to support their client technical requirements, reducing both the cost and time in the process.