Polyworks Inspector

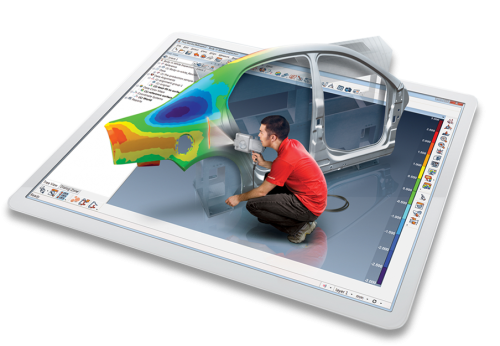

Align

The inspection of a component always begins with the alignment of a datum reference system defined either on the CAD model or 2D drawing. This alignment is probably the single most important part of quality control inspection as ‘poor’ or incorrect alignments can mean incorrect inspection and thus not giving engineers the correct feedback they need to make decisions. Polyworks has class leading alignment tools to align from:

- Surfaces or cross-sections allowing completely freeform fit or constrained in a particular axis or rotation.

- GD&T datum reference based alignments

- RPS – Reference Point System alignments

- Virtual Gauge alignments – Gap and Flush, caliper and air foil.

.

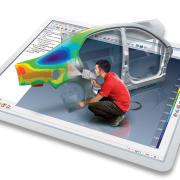

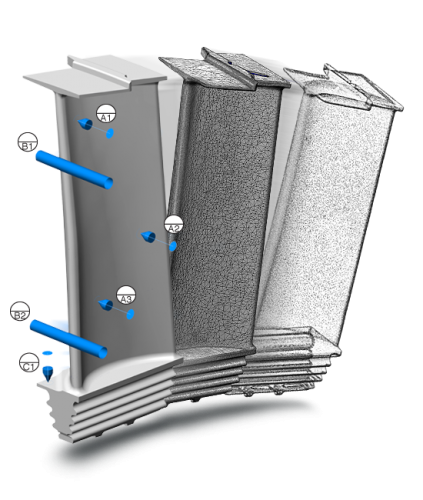

Measure

The extraction of measured dimensions from either point cloud or polygonal models is at the core of the Inspector module. Define exact parameters for the accurate extraction of surface, boundary, and cross-sections measurements. Once defined these measurements can be saved into part inspection sequences to rapidly measure multiple components and produce consistent reports.

Polworks Inspector can measure:

- Surface, boundaries and cross-sections to nominal data

- GD&T dimensions and datums

- Real-time assembly guidance

- Advanced dimensions – Flush and Gap, Profile Radius, Airfoil measurement and thickness

.

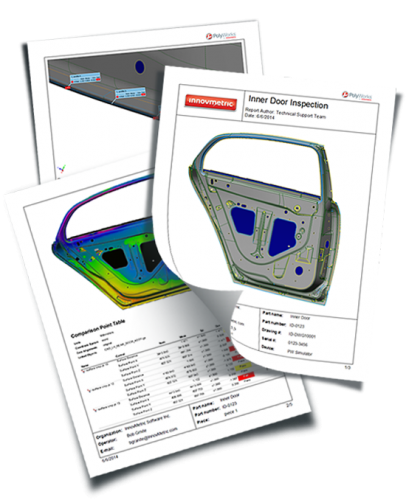

Report

Polyworks reporting module has advanced technology that enables graphics and inspection tables to be defined in a particular layout and format, defined by the end-user, to create reports bespoke to each company and exactly as they require the ‘look and feel’. This template is accurately repeated and updated for multiple part inspection requiring no user intervention by the operator.

Polworks Viewer offers a unique way to share inspection projects companywide without the need for additional software licences.