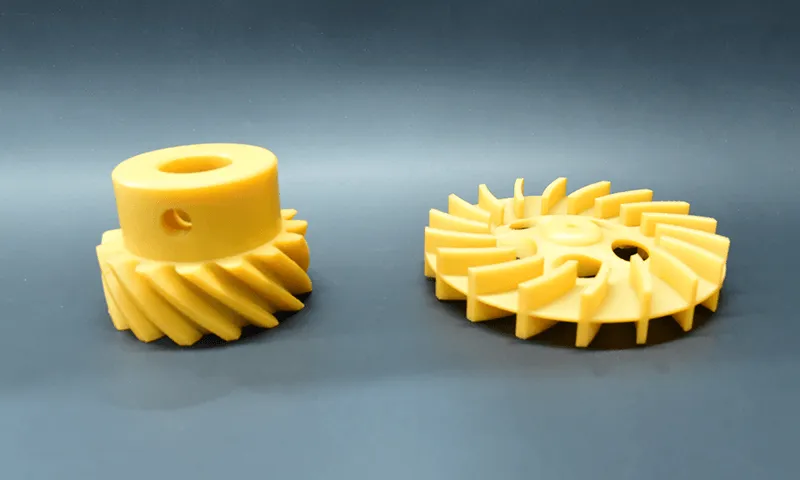

High Temperature SLA Resin

Precision SLA parts that hold their shape up to 227°C.

This is a high temperature industrial grade SLA resin, engineered for parts that must hold shape and accuracy at elevated temperatures. It has a heat deflection temperature (HDT) of up to 227°C after simple post-processing and is a strong choice for functional prototypes and production-style components where conventional resins would soften or creep.

Why choose High Temp 220D?

-

Exceptional heat resistance: HDT 227°C @ 0.455 MPa (and 170°C @ 1.82 MPa) for demanding thermal environments.

-

High stiffness and strength: Shore D 90, flexural modulus 4321 MPa, flexural strength 116 MPa.

- Reliable detail & finish: Designed to deliver excellent precision and dependable surface quality from SLA builds.